WOVEN WIRE MESH

Consistent Performance. Proven Durability.

Our woven wire screens are engineered for optimal screening performance across a wide range of applications. With high tensile strength and customizable aperture sizes, our woven mesh ensures reliable sizing and extended wear life. Ideal for mining, aggregate, and industrial applications, our wire mesh screens deliver precision and longevity in every use.

Precision apertures for accurate sizing

Achieve consistent cut-size and open area similar to traditional wire mesh screens.

Custom options for any screening need

Available in multiple wire diameters, weave types, and panel sizes for maximum flexibility.

Easy to install and replace

Modular designs and hook styles allow for fast installation and reduced downtime.

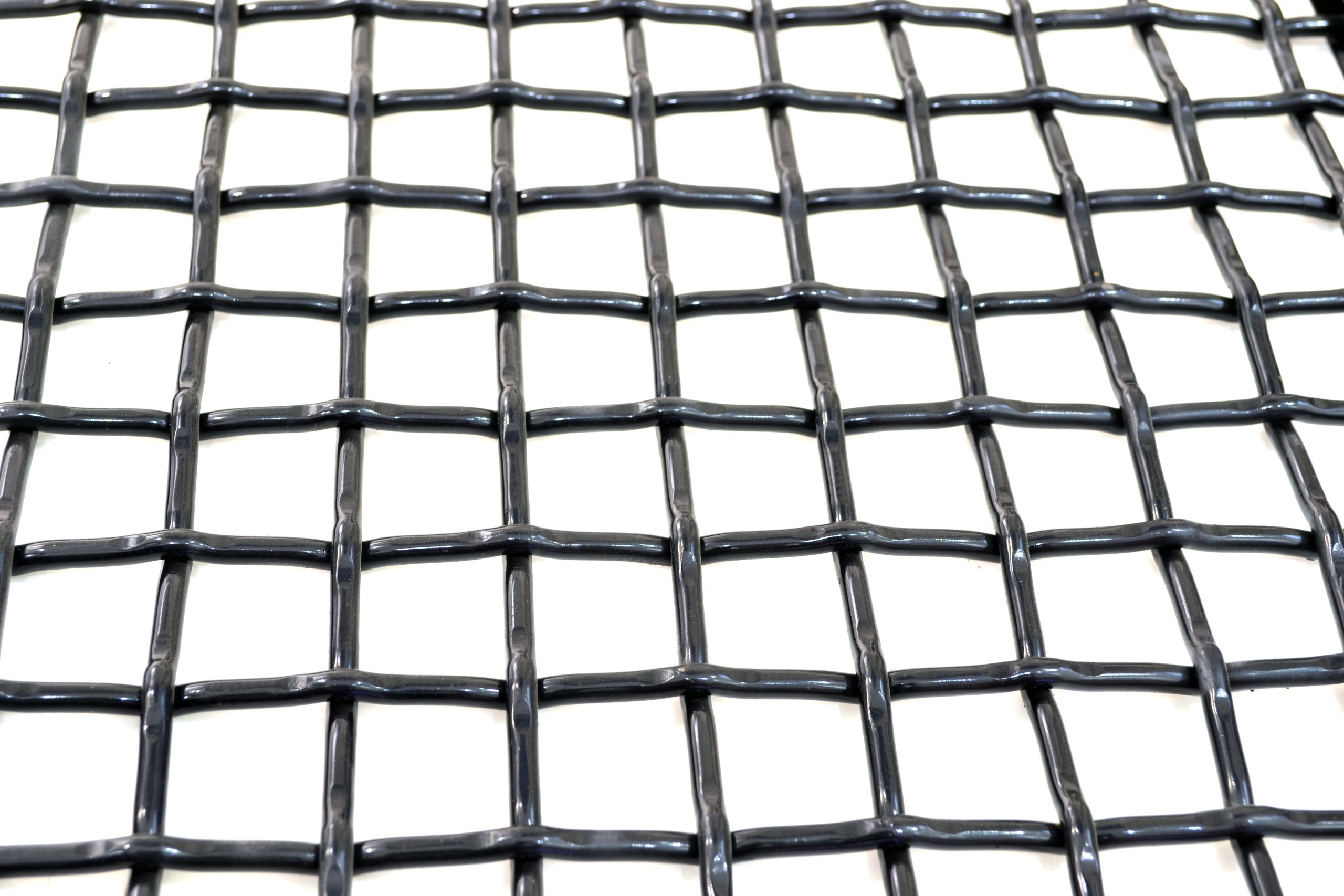

Square Woven Metal Wire Mesh

Our square woven wire mesh panel is a high-strength and wear-resistant screening media. It is woven from high-tensile steel or stainless steel wires, ideal for heavy-duty screening in mining, aggregate, and coal industries.

Screen Size:

Customizable (Standard: 1m x 2m)

Opening:

3mm-60mm

Wire Diameters:

1.6mm-12mm

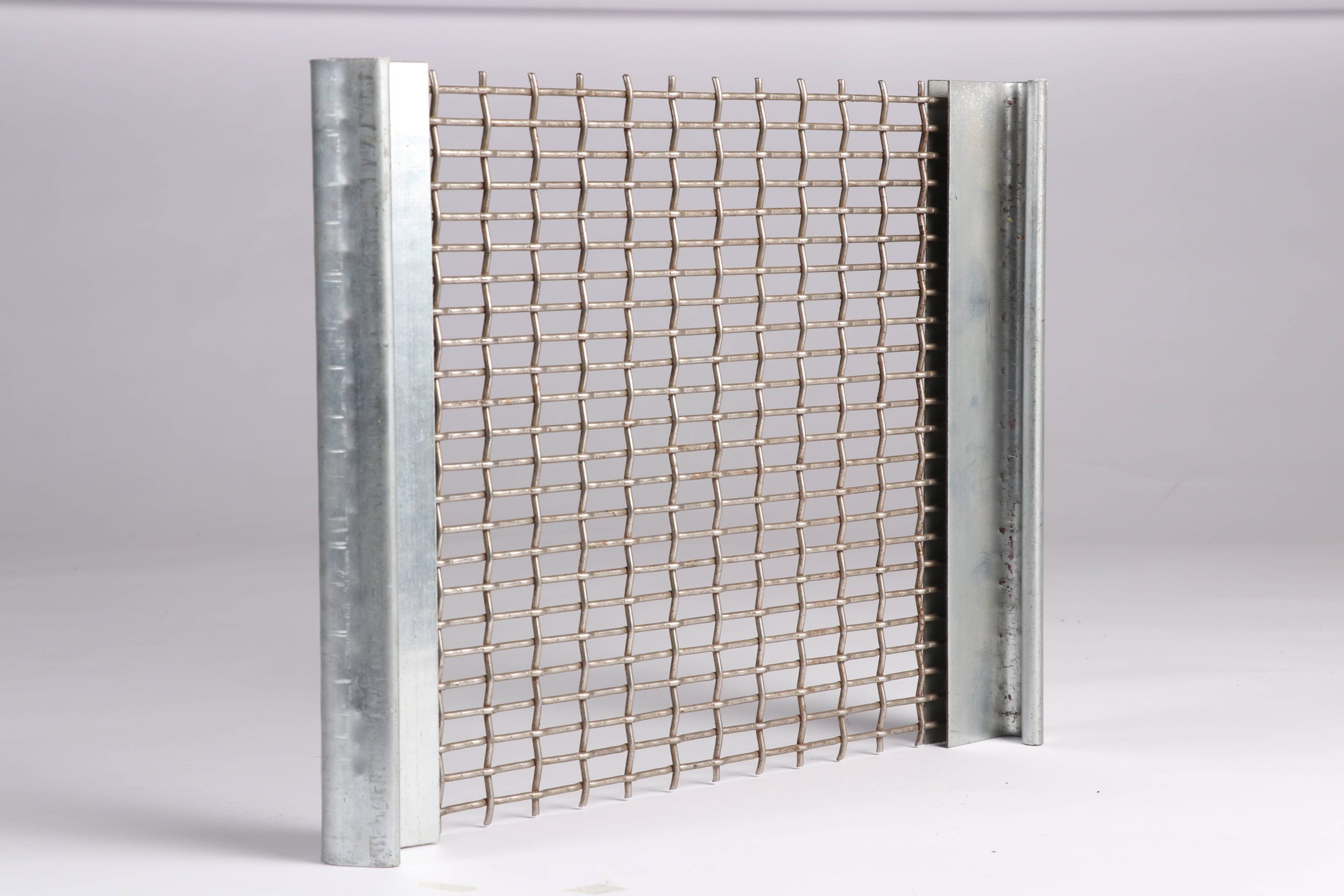

We offer various edge types and fastening methods for easy installation on different screen decks:

Hooked edges (U-shape)

Flat steel or sheet edge reinforcement

Cross bars or support rods

Customized mounting holes and fixing parts

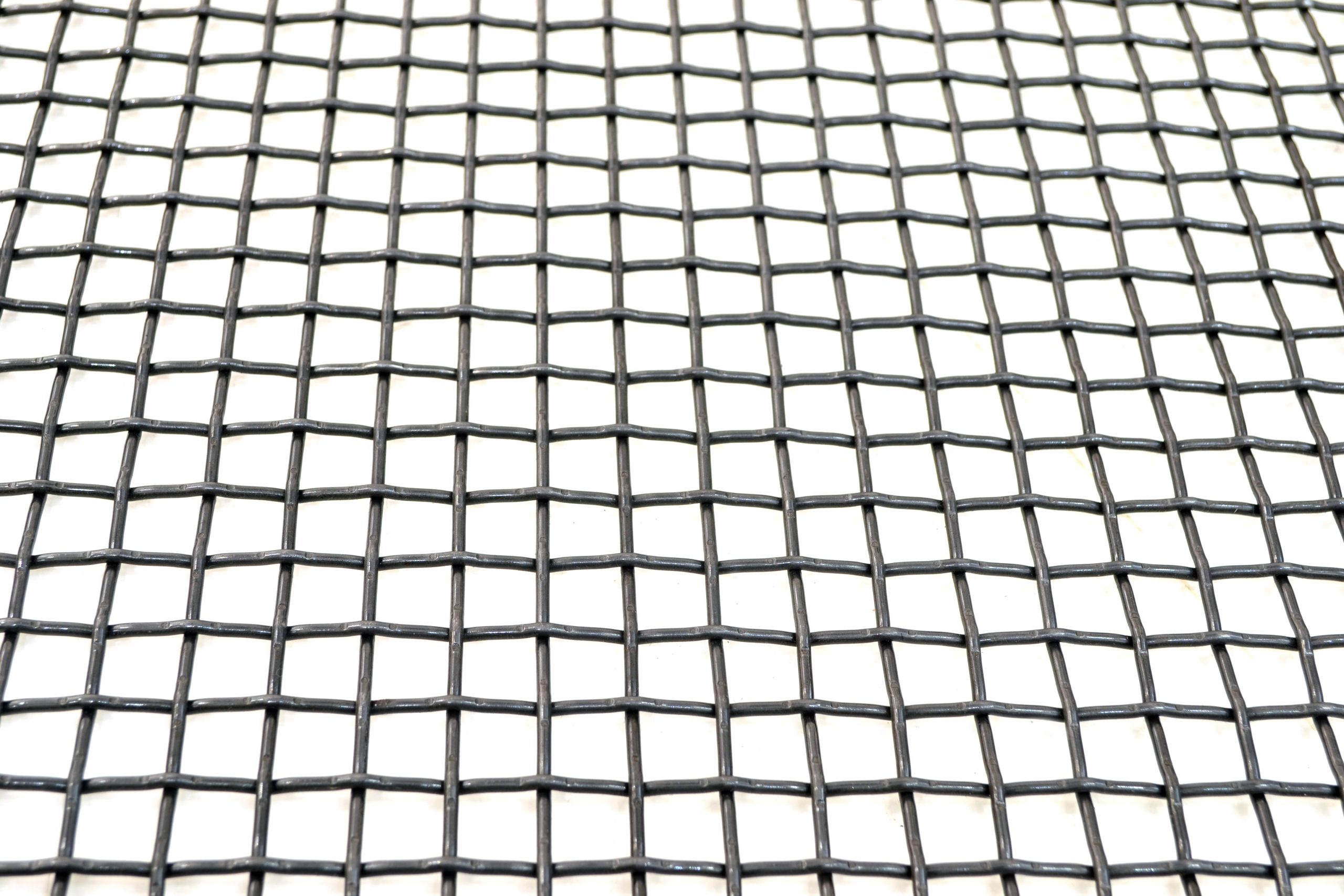

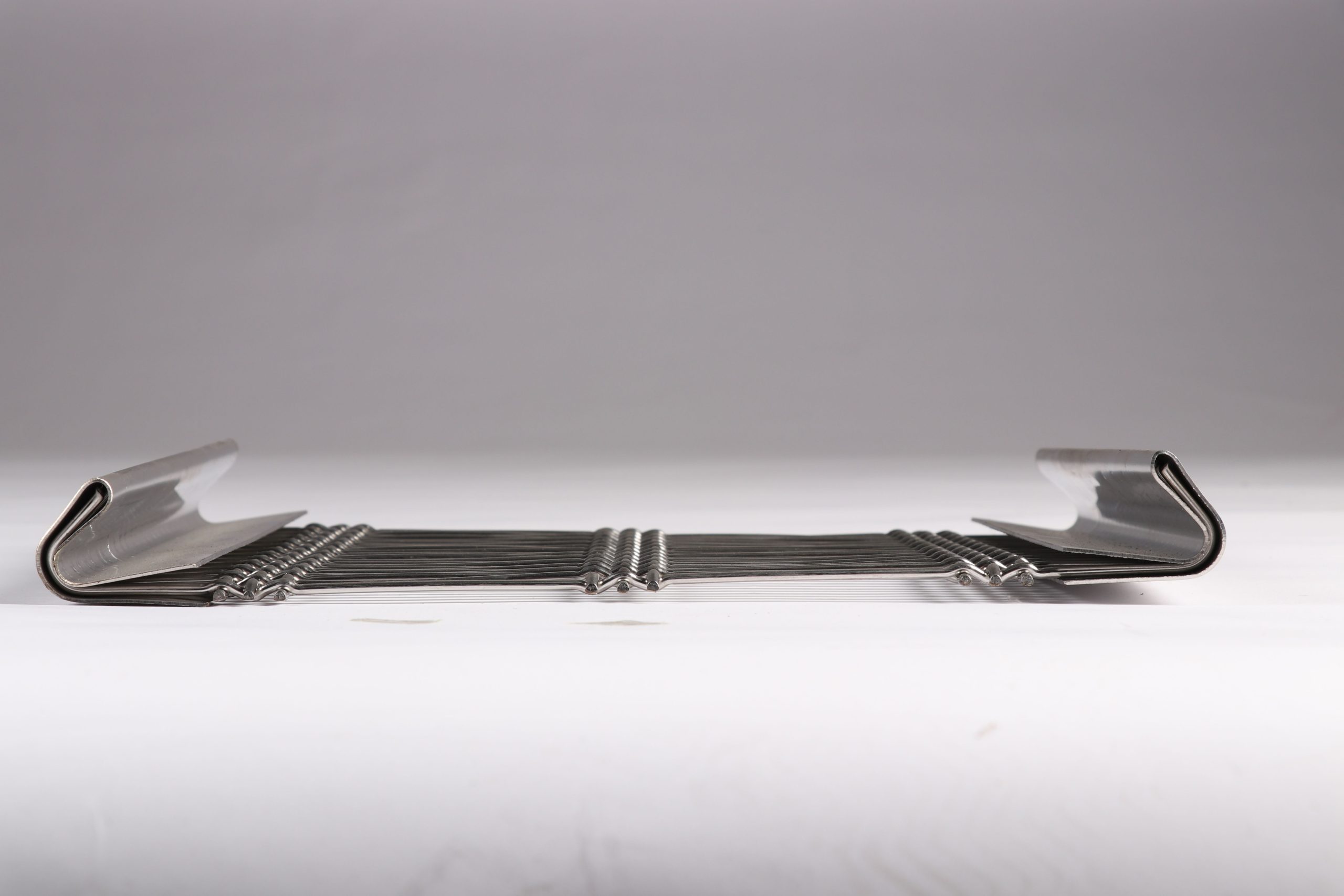

Long Slot Woven Metal Wire Mesh

Long slot woven wire mesh is manufactured by interweaving high-strength steel wires into a rectangular opening pattern, allowing elongated materials to pass through while maintaining particle control.

This mesh type is widely used in coal processing, crushed stone classification, wet screening, and materials prone to clogging.

Available in 65Mn, stainless steel, and galvanized steel, it offers high wear resistance and extended service life.

Screen Size:

Standard panel width: 1.0m / 1.2m / 1.5m

Length: Up to 3.6m (custom sizes available)

Aperture Range:

Slot openings: from 1.5 × 20 mm to 6 × 60 mm

Wire Diameter:

Wire diameter: 1.2 mm – 8.0 mm

Square openings with uniform aperture for consistent sizing.Available in plain weave,or lock crimp.Accurate tolerance: ±0.2mm.Built to resist blinding and plugging under tough conditions

Wire Material:

65Mn High Tensile Steel (for abrasion resistance)

Stainless Steel 304 / 316 (for corrosion resistance)

Galvanized Steel (for general use)

Wire Material:

Suitable for primary and secondary screening

We offer various edge types and fastening methods for easy installation on different screen decks:

Hooked edges (U-shape)

Flat steel or sheet edge reinforcement

Cross bars or support rods

Customized mounting holes and fixing parts

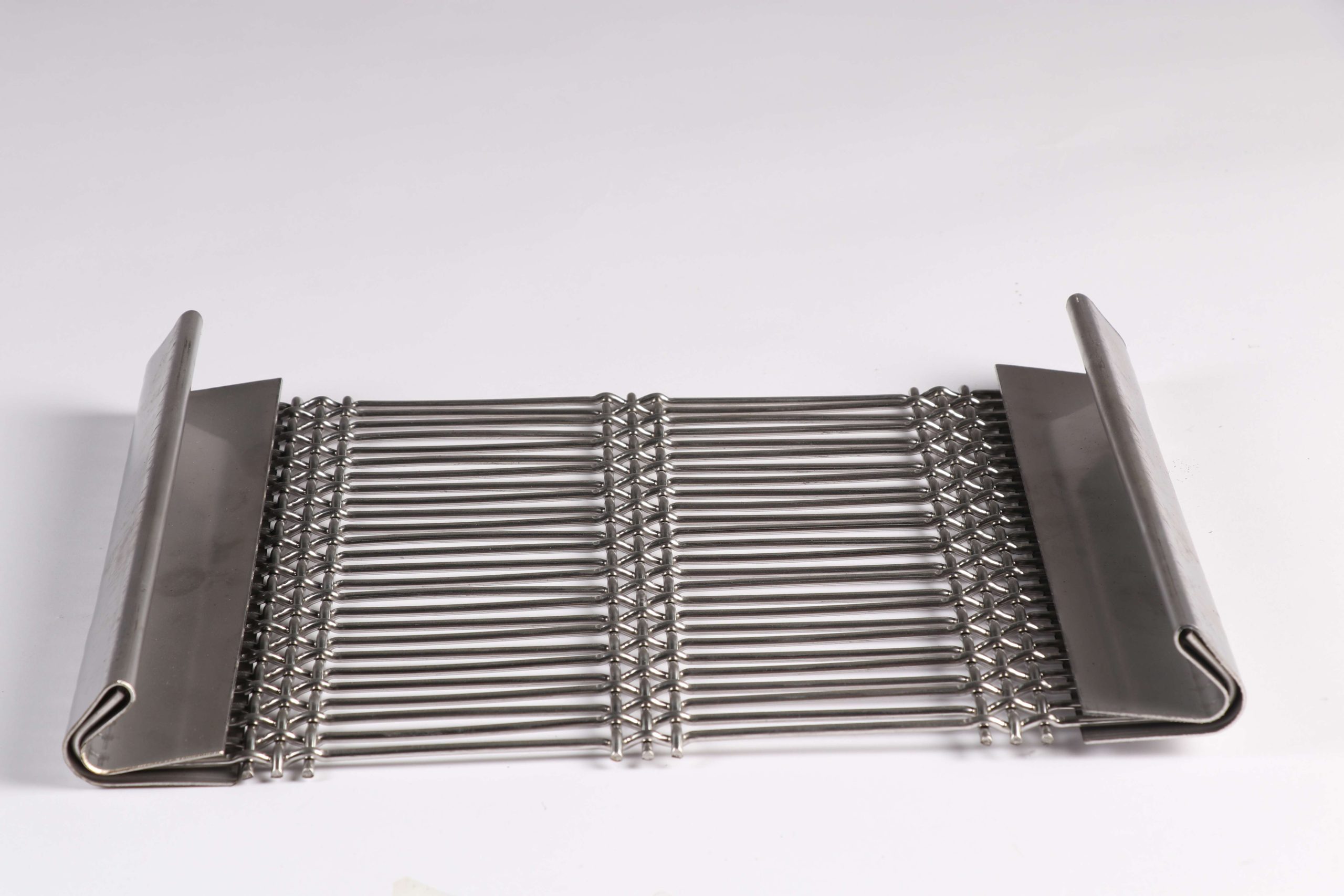

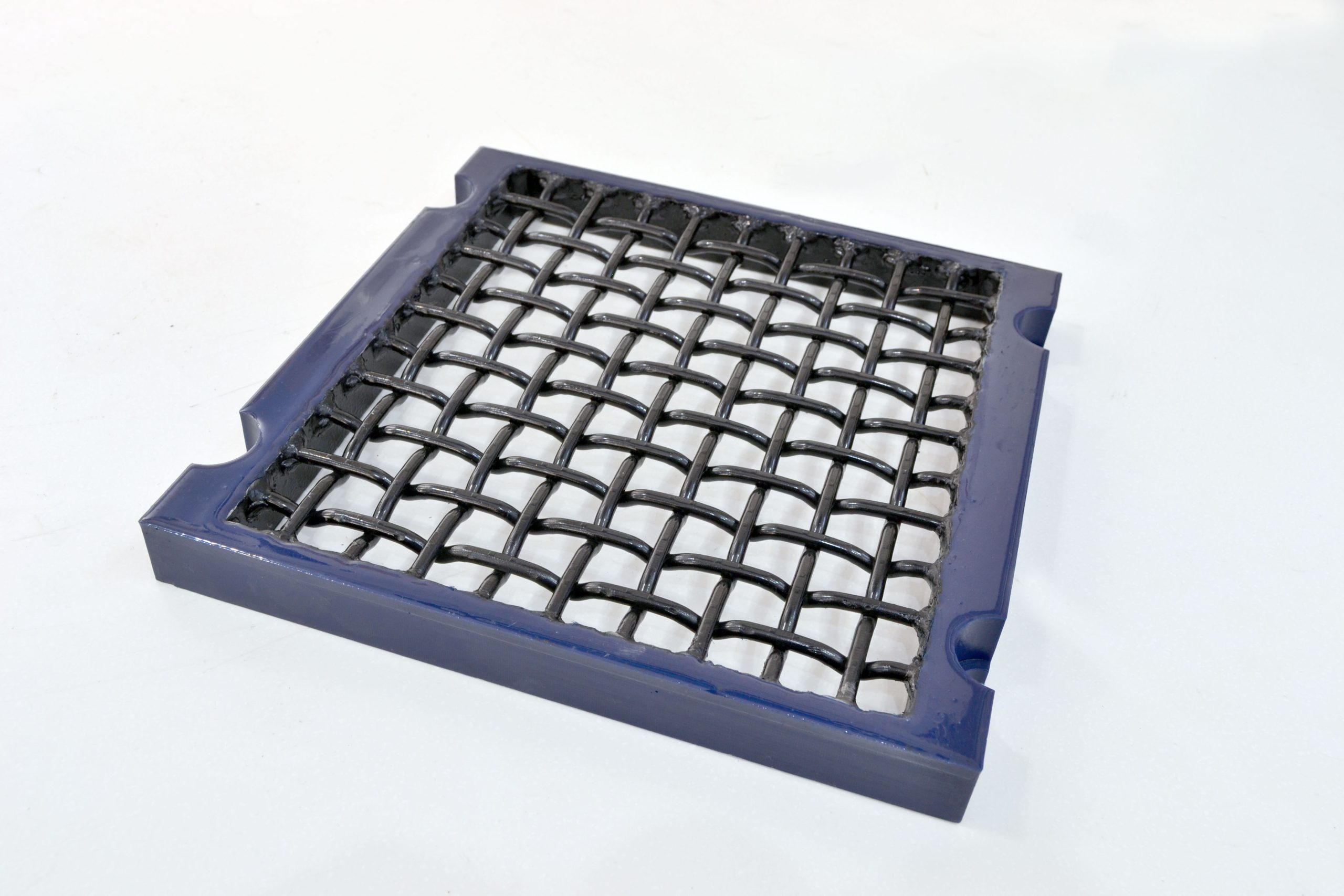

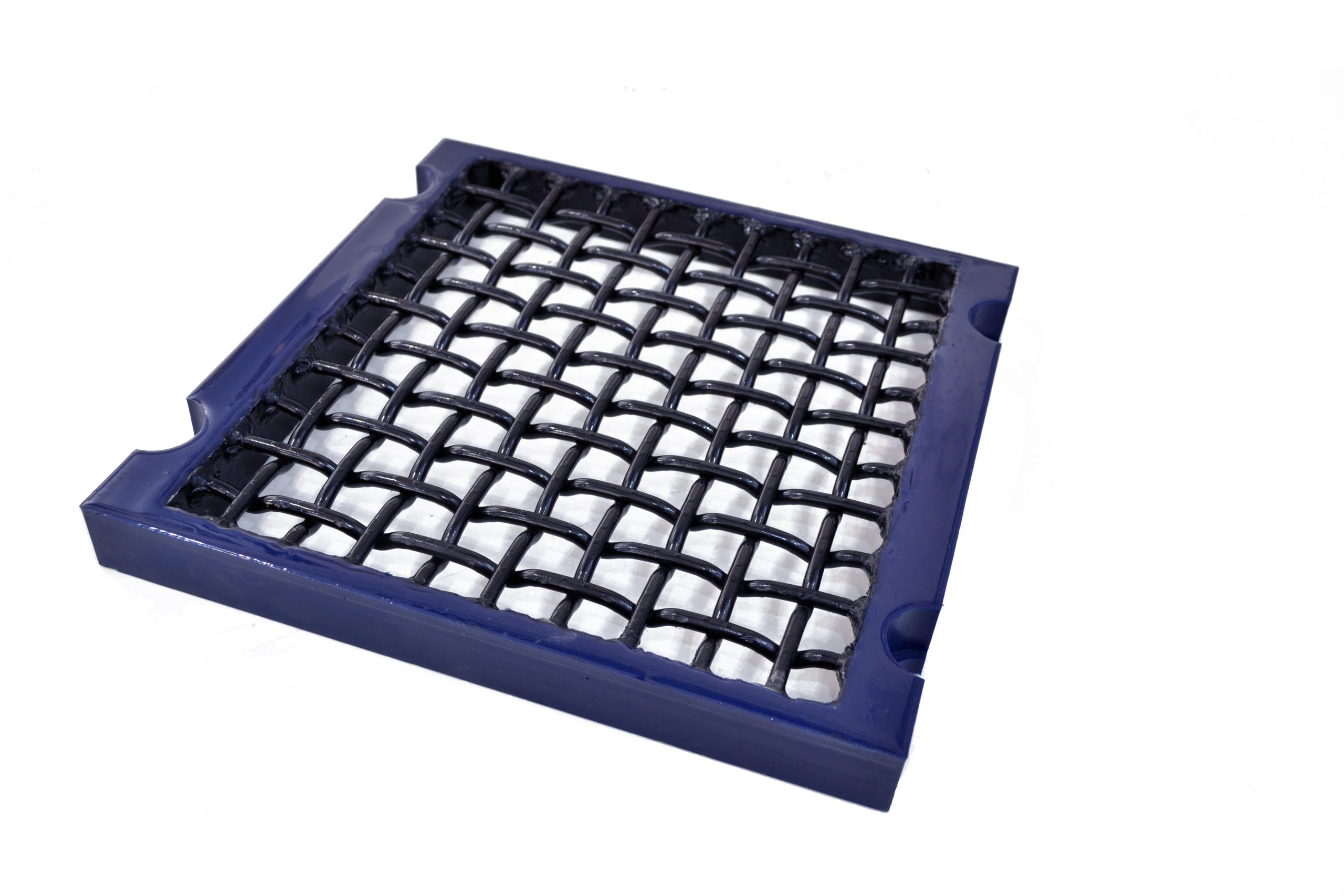

Polyurethane Screen Panel with Embedded Woven Wire

Our square woven wire mesh panel is a high-strength and wear-resistant screening media. It is woven from high-tensile steel or stainless steel wires, ideal for heavy-duty screening in mining, aggregate, and coal industries.

Panel Size:

Customizable (Standard: 30mm,35mm,40mm,45mm,50mm)

Aperture Range:

2mm to 60mm

Square openings with uniform aperture for consistent sizing.Available in plain weave,or lock crimp.Accurate tolerance: ±0.2mm.Built to resist blinding and plugging under tough conditions

Wire Material:

High-manganese steel / SS304 / SS316

Wire Diameters:

1.6mm-12mm

Our polyurethane screen panels are available with multiple installation methods to fit various screening machines. Standard options include:

Pin & Sleeve (Tensioning Pin) – Quick and secure installation using tension pins for fixed placement.

Side or Center Hold-down Slots – Designed with groove-type edges to easily lock into slot rails.

Bolt-down Type – Equipped with countersunk holes for direct bolt fixing to the deck.

Hook Strip Type – For tensioned screen decks, compatible with hook-style mounting.

Custom slot profiles and locking methods can be designed based on your machine requirements.

About Benaili

Benaili Wire Mesh Products Co., Ltd. is a trusted manufacturer of high-performance screening media for the mining and quarrying industries.

Based in Anping, China – the Wire Mesh Capital of the World.